Effects on Farrowing: Stall Size and Heat Lamps

go.ncsu.edu/readext?824310

en Español / em Português

El inglés es el idioma de control de esta página. En la medida en que haya algún conflicto entre la traducción al inglés y la traducción, el inglés prevalece.

Al hacer clic en el enlace de traducción se activa un servicio de traducción gratuito para convertir la página al español. Al igual que con cualquier traducción por Internet, la conversión no es sensible al contexto y puede que no traduzca el texto en su significado original. NC State Extension no garantiza la exactitud del texto traducido. Por favor, tenga en cuenta que algunas aplicaciones y/o servicios pueden no funcionar como se espera cuando se traducen.

Português

Inglês é o idioma de controle desta página. Na medida que haja algum conflito entre o texto original em Inglês e a tradução, o Inglês prevalece.

Ao clicar no link de tradução, um serviço gratuito de tradução será ativado para converter a página para o Português. Como em qualquer tradução pela internet, a conversão não é sensivel ao contexto e pode não ocorrer a tradução para o significado orginal. O serviço de Extensão da Carolina do Norte (NC State Extension) não garante a exatidão do texto traduzido. Por favor, observe que algumas funções ou serviços podem não funcionar como esperado após a tradução.

English

English is the controlling language of this page. To the extent there is any conflict between the English text and the translation, English controls.

Clicking on the translation link activates a free translation service to convert the page to Spanish. As with any Internet translation, the conversion is not context-sensitive and may not translate the text to its original meaning. NC State Extension does not guarantee the accuracy of the translated text. Please note that some applications and/or services may not function as expected when translated.

Collapse ▲Effect of stall size, number of heat lamps during farrowing: Part 3

Suzanne M. Leonard, Brett C. Ramirez, North Carolina State University, Iowa State University | October 01, 2021

In this large-scale field study comparing three farrowing stall layouts (TSL – traditional stall layout, ECSL – expanded creep stall layout, ESCSL – expanded sow and creep stall layout) and using one or two heat lamps (1HL or 2HL), production data determined there were no differences in average daily weight gain or prewean piglet mortality due to experimental treatment. A custom camera system was used to monitor sow posture and feeding and drinking behaviors. Sows in the expanded sow and creep stall layout (ESCSL) spent more time lying and less time sitting, which could indicate an improvement in sow ease of movement or wellbeing. The custom camera system captured images of the entire stall and creep area, allowing for analysis of piglet behavior.

Piglet Behavior Results

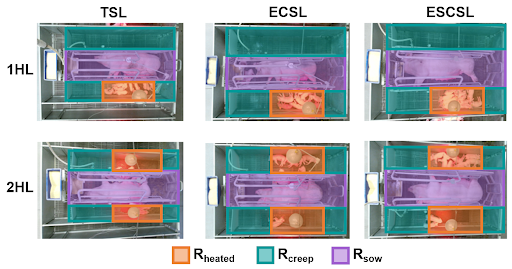

The digital images taken during the day while the facility lights were on (05:30 to 19:00) were used to determine piglet location using a custom algorithm developed in Python. Piglets were labeled as being either directly in the sow stall region (Rsow), in the creep area directly under the heat lamp (Rheated), or in any other area of the creep (Rcreep; Figure 1). In each image, the proportion of piglets in each region of the stall were counted by the computer algorithm. These values were averaged over the whole day to determine how frequently the piglets were in each region of the farrowing stall. Piglet location was recorded from the day of farrowing to three days post-farrowing, as well as days 7, 14, and 21 of lactation (Leonard et al., 2021).

Figure 1. A custom camera system counted the proportion of piglets in each region of the farrowing stalls. Regions were labeled as the creep area directly under the heat lamp (Rheated), in any other part of the creep area (Rcreep), or in the sow crate area (Rsow). Experimental treatments were traditional stall layout (TSL), expanded creep stall layout (ECSL), and expanded sow and creep stall layout (ESCSL) and were tested with either one or two heat lamps (1HL or 2HL).

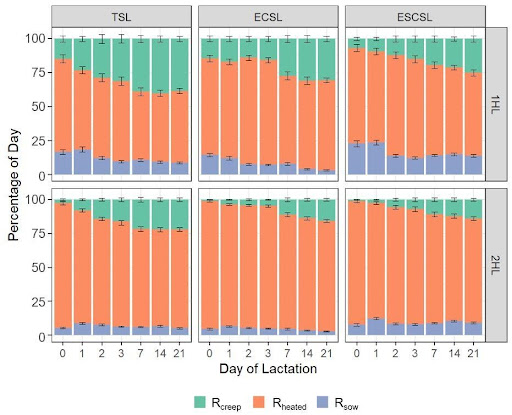

The amount of time piglets spent in each area of the stall was influenced by day of lactation, stall layout, and heat lamp treatment. Statistical interactions between day of lactation and stall layout as well as day of lactation and heat lamp treatment suggested that the way piglets utilized the spaces within the stall changed as they aged. On average, piglets with 2HL spent 4.8 hours more per day in the heated areas than piglets with 1HL (Figure 3). When piglets are under the heat lamp their energy expenditures for thermoregulation are reduced, as the heat lamp creates a warmer environment closer to thermoneutral for the piglets. However, regardless of the number of heat lamps, there were no differences in piglet mortality or average daily weight gain, suggesting that the second heat lamp does improve piglet welfare by better meeting thermal needs but does not create a measurable change in productivity.

Figure 3. Percentage of time on each day of lactation piglets spent in each region of the farrowing stall by experimental treatment. Piglet location was identified as Rcreep when in the creep area, Rheated when directly under the heat lamp, or Rsow when in the sow crate region. Day of farrowing is indicated as Day of Lactation 0 and was designated from 00:00 to 23:59. Error bars indicate standard error. Experimental treatments were traditional stall layout (TSL), expanded creep stall layout (ECSL), and expanded sow and creep stall layout (ESCSL) and were tested with either one or two heat lamps (1HL or 2HL).

No relationships were found between time spent in each piglet location and pre-weaning mortality or overlay. However, the computer program did not track individual piglets and only recorded overall litter location information. There is likely a relationship between individual piglet location and mortality, in particular mortalities due to overlay, as the piglets must be in the sow region of the stall in order to be crushed by the sow.

Sow and Piglet Behavior

Though the sow crate was centered in the farrowing stall to create two equal sized creep areas, the piglets did not use both sides of the creep equally. The piglets spent more time on the side of the creep with the sow’s udder, in both the 1HL and 2HL treatments. This demonstrates that piglets preferred udder access over heat lamp access, suggesting that the 2HL treatment could provide the additional needed warmth for neonatal piglets regardless of sow lying orientation. In the 1HL treatment, sows did not change their lying orientation behavior after the heat lamps were turned on. This indicates that the heat lamps at the heights and locations tested in this study do not cause direct thermal stress or discomfort for the sow.

The combination of productivity and behavior data in this study of 427 sows and their litters provides insight into how farrowing stall layout and number of heat lamps can impact productivity and behavior.

Sources

Leonard, S.M., Xin, H., Brown-Brandl, T.M., Ramirez, B.C., Johnson, A.K., Dutta, S., Rohrer, G.A. (2021). Effects of farrowing stall layout and number of heat lamps on sow and piglet behavior. Applied Animal Behavior Science, 239(2021) 105334. doi: 10.1016/j.applanim.2021.105334

Leonard, S.M., Xin, H., Brown-Brandl, T.M., Ramirez, B.C., Dutta, S., Rohrer, G.A. (2020). Effects of farrowing stall layout and number of heat lamps on sow and piglet productivity. Animals. 10(2):348. doi: 10.3390/ani10020348

Leonard, S.M., Xin, H., Brown-Brandl, T.M., Ramirez, B.C. (2019). Development and application of an image acquisition system for characterizing sow behaviors in farrowing stalls. Computers and Electronics in Agriculture. doi: 10.1016/j.compag.2019.104866